top of page

SOLUTIONS

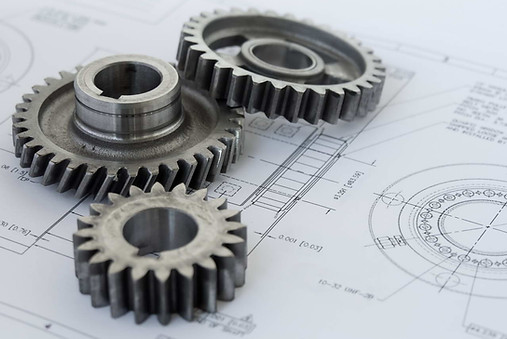

Didsbury Engineering not only has a wide array of off-the-shelf products available to customers, we can also draw on our experienced design team to deliver high quality, cost effective engineering design solutions to match a client’s exact needs. Using our highly structured Workflow process to manage our projects, we ensure our work is delivered on time and to budget so long term relationships can be formed with the companies we serve.

bottom of page